The application fields of extruders mainly include the following

aspects:

1. Plastics industry: Used for the production of various plastic

pipes, profiles, films, sheets, etc.

2. Rubber industry: To process rubber products.

3. Food industry: For manufacturing food extrudates such as snack

foods.

4. Chemical industry: In the production of some chemical products.

5. Cable industry: To produce cable insulation and sheathing

materials.

6. Building materials industry: Applied in the manufacturing of

building materials with specific shapes.

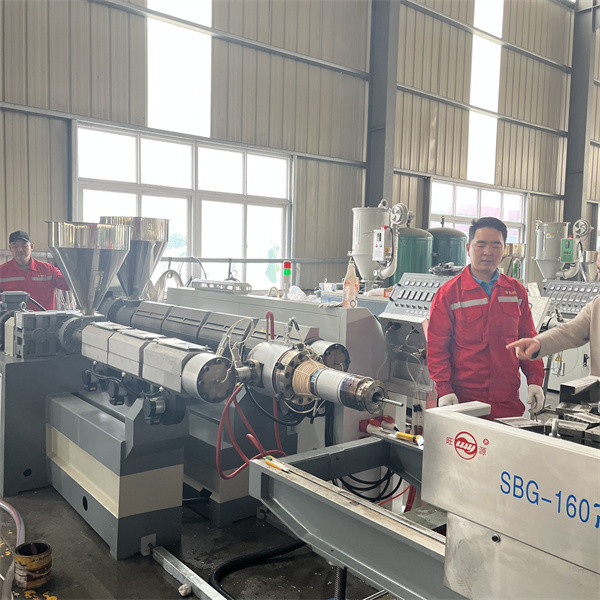

The performance characteristics of the extruder can be described as

follows:

1. High extrusion efficiency, capable of rapidly processing raw

materials.

2. Stable operation, ensuring continuous and smooth extrusion

process.

3. Precise control, enabling accurate adjustment of extrusion

parameters.

4. Good compatibility, suitable for processing various types of

plastic materials.

5. Strong power, providing sufficient driving force for extrusion.

6. Low energy consumption, achieving energy-efficient operation.

7. Durable and reliable, with a long service life and less prone to

breakdowns.

8. Advanced temperature control system, maintaining stable

temperature during extrusion.

9. Fine extrusion quality, ensuring the uniformity and quality of

the extruded products.

10. Easy to maintain and operate, facilitating daily use and

management.

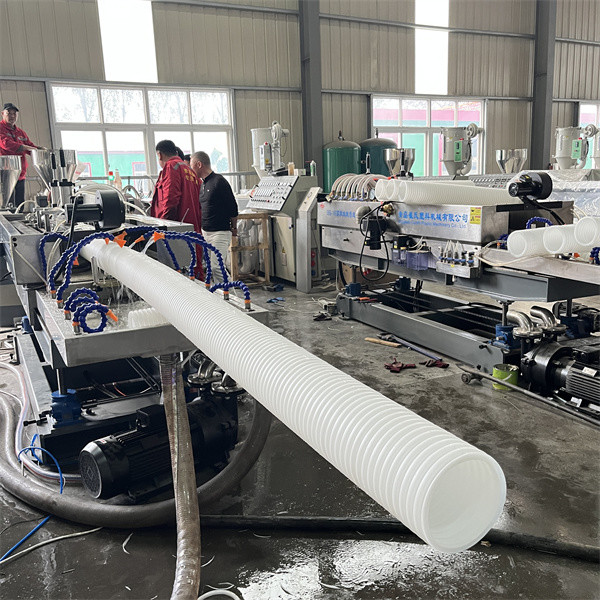

The working principle of the double-wall corrugated pipe extrusion

equipment is as follows. Firstly, the raw materials are fed into

the extruder. The extruder then melts and homogenizes the materials

under controlled temperature and pressure. The molten plastic is

forced through a die that is specifically designed to form the

characteristic double-wall corrugated structure. As the molten

material exits the die, it begins to take on the desired shape. A

vacuum is often applied to assist in the formation and

stabilization of the corrugated walls. At the same time, cooling

systems are employed to rapidly cool and solidify the extruded

pipe. The continuous extrusion process allows for the production of

long lengths of double-wall corrugated pipe. Various control

mechanisms are in place to ensure precise dimensions, consistent

quality, and smooth operation throughout the extrusion process.